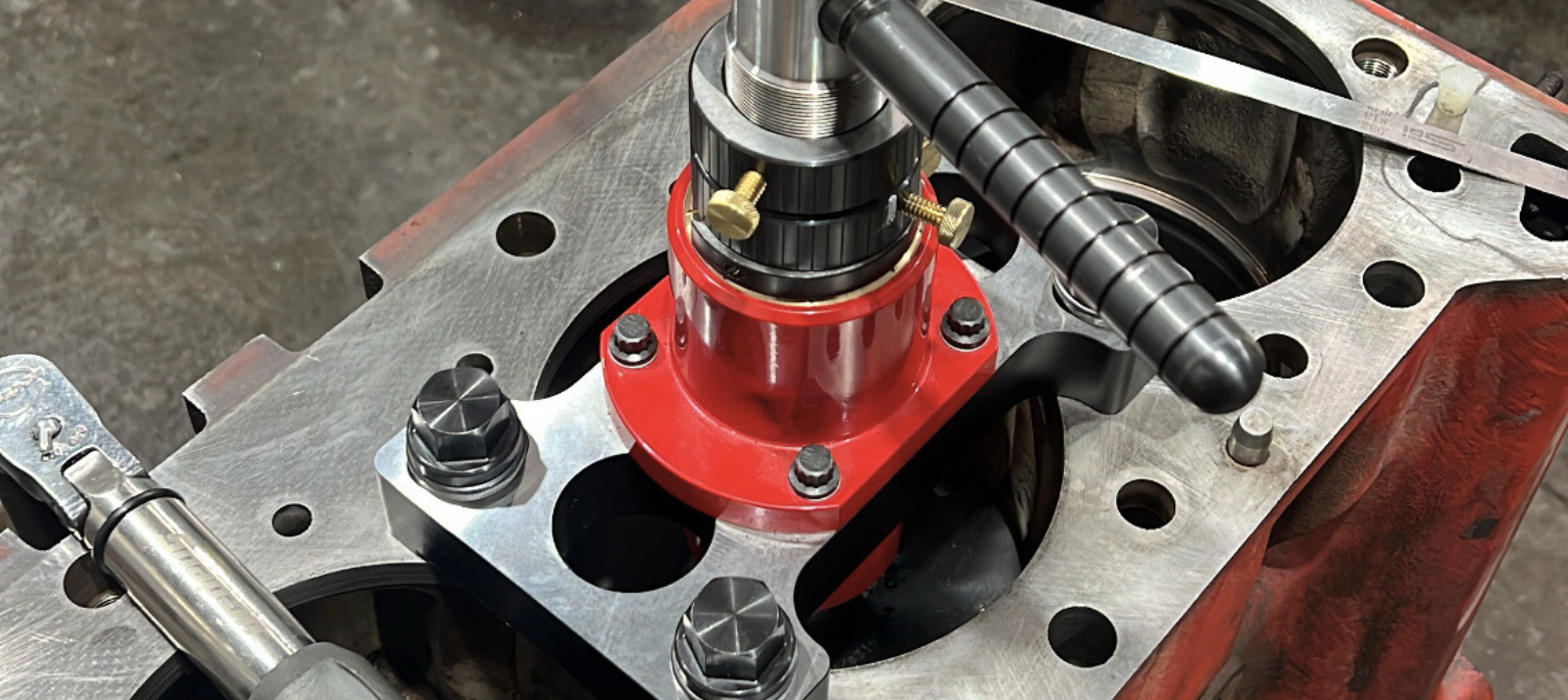

Engine counterbore cutting service plays a pivotal role in prolonging the lifespan of internal combustion engines. This service, often overlooked, is critical for maintaining engine integrity and preventing costly damages. In this article, we delve into the importance of engine counterbore cutting and its impact on engine performance and longevity.

- Precision Restoration: Engine counterbore cutting involves the precise restoration of cylinder head and block surfaces. Over time, these surfaces can become uneven due to wear, corrosion, or overheating. By machining the counterbore, any irregularities or imperfections are meticulously corrected, ensuring a smooth and uniform surface for optimal engine operation.

- Sealing Integrity: A properly machined counterbore is essential for achieving proper sealing between the cylinder head gasket and the engine block. Any irregularities in the counterbore can compromise the sealing integrity, leading to leaks, loss of compression, and ultimately, engine failure. Counterbore cutting ensures a tight seal, minimizing the risk of coolant or combustion gas leaks.

- Preventing Head Gasket Failure: Head gasket failure is a common issue in engines, often attributed to inadequate sealing between the cylinder head and block. Uneven or warped surfaces can exert uneven pressure on the head gasket, increasing the likelihood of failure. By machining the counterbore to precise specifications, the risk of head gasket failure is significantly reduced, promoting engine reliability.

- Optimizing Performance: An accurately machined counterbore contributes to improved engine performance. By ensuring proper sealing and alignment of engine components, counterbore cutting minimizes friction, reduces wear, and enhances overall engine efficiency. This results in smoother operation, increased power output, and better fuel economy.

- Cost-Efficiency: Investing in engine counterbore cutting service is a cost-effective measure in the long run. By addressing surface irregularities early on, potential issues such as head gasket failure or cylinder head damage are mitigated, preventing more extensive and expensive repairs down the line. Regular maintenance, including counterbore cutting, can extend the service life of the engine and save owners significant time and money.

Conclusion: Engine counterbore cutting service is a fundamental aspect of engine maintenance, crucial for preserving engine integrity, reliability, and performance. By addressing surface irregularities and ensuring proper sealing, counterbore cutting plays a vital role in preventing costly damages and maximizing engine longevity. For engine owners and enthusiasts committed to optimal performance and durability, investing in professional counterbore cutting service is a wise decision.